Tesnit® BA-203

Product Description

Gasket Material for Medium-Level Loads

TESNIT® BA-203 is a special gasket material based on aramid fiber and NBR. It has good resistance to water, gas, oil, and fuel.

show more...

Application Areas

For medium-level loads;

Water

Gas

Oil

A gasket material with good resistance to fuel.

Surface Treatment: Upon request, the gasket material surface is subjected to graphite, PTFE, and antistatic coating processes.

show more...

Main Components

Aramid fiber, NBR

Approval: Germanischer Lloyd, DVGW KTW, DVGW W270

show more...

Standard Sheet Dimensions

Width x Height (mm): 1000 x 1500 | 1500 x 1500 | 3000 x 1500 | 4500 x 1500

Thickness (mm): 0.5 | 0.8 | 1.0 | 1.5 | 2.0 | 3.0

show more...

* Other sizes and thicknesses can be accommodated upon request.

General application area, provided that chemical compatibility conditions and known installation principles are applied.

Maximum performance is ensured by adhering to the appropriate technical values in connection design and gasket installation. It is recommended to seek consultancy services.

Limited application area. Technical consultancy is mandatory.

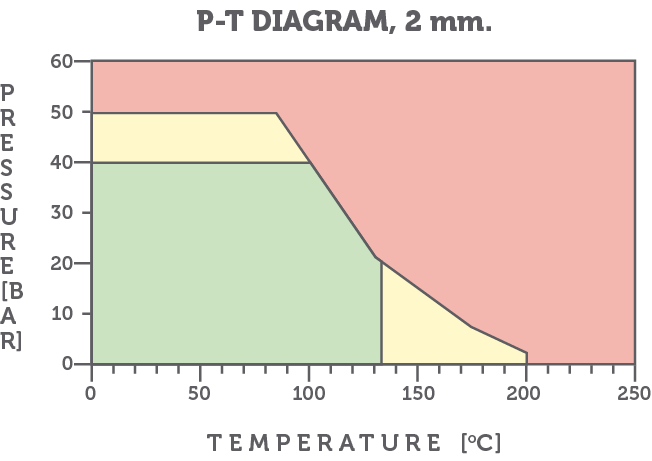

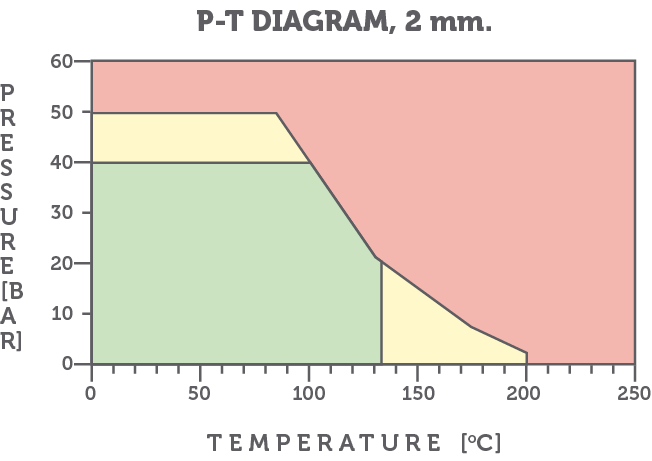

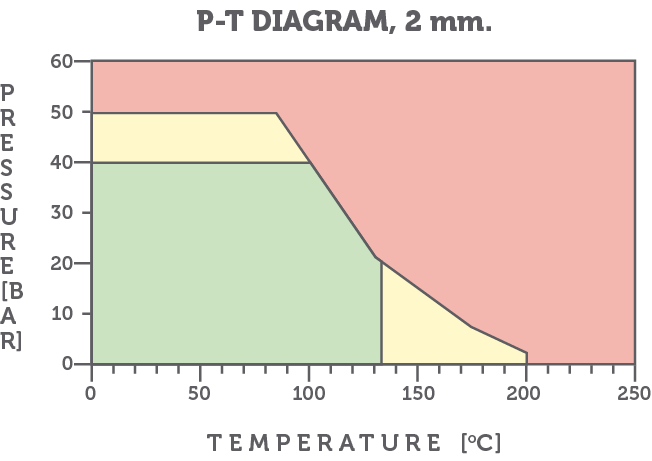

In a known application, the best method to determine gasket compatibility is by using the P-T diagram. The highest values of P-T can be misleading. Maximum temperature and maximum pressure should not be used simultaneously. Maximum values are provided purely for indicative purposes. These values are related both to the gasket material properties and to the operating conditions. It is recommended to use the P-T diagram when selecting a gasket.

Tesnit® BA-203

Product Description

Gasket Material for Medium-Level Loads

TESNIT® BA-203 is a special gasket material based on aramid fiber and NBR. It has good resistance to water, gas, oil, and fuel.

show more...

Application Areas

For medium-level loads;

Water

Gas

Oil

A gasket material with good resistance to fuel.

Surface Treatment: Upon request, the gasket material surface is subjected to graphite, PTFE, and antistatic coating processes.

show more...

Main Components

Aramid fiber, NBR

Approval: Germanischer Lloyd, DVGW KTW, DVGW W270

show more...

Standard Sheet Dimensions

Width x Height (mm): 1000 x 1500 | 1500 x 1500 | 3000 x 1500 | 4500 x 1500

Thickness (mm): 0.5 | 0.8 | 1.0 | 1.5 | 2.0 | 3.0

show more...

* Other sizes and thicknesses can be accommodated upon request.

General application area, provided that chemical compatibility conditions and known installation principles are applied.

Maximum performance is ensured by adhering to the appropriate technical values in connection design and gasket installation. It is recommended to seek consultancy services.

Limited application area. Technical consultancy is mandatory.

In a known application, the best method to determine gasket compatibility is by using the P-T diagram. The highest values of P-T can be misleading. Maximum temperature and maximum pressure should not be used simultaneously. Maximum values are provided purely for indicative purposes. These values are related both to the gasket material properties and to the operating conditions. It is recommended to use the P-T diagram when selecting a gasket.

Tesnit® BA-203

Product Description

Gasket Material for Medium-Level Loads

TESNIT® BA-203 is a special gasket material based on aramid fiber and NBR. It has good resistance to water, gas, oil, and fuel.

show more...

Application Areas

For medium-level loads;

Water

Gas

Oil

A gasket material with good resistance to fuel.

Surface Treatment: Upon request, the gasket material surface is subjected to graphite, PTFE, and antistatic coating processes.

show more...

Main Components

Aramid fiber, NBR

Approval: Germanischer Lloyd, DVGW KTW, DVGW W270

show more...

Standard Sheet Dimensions

Width x Height (mm): 1000 x 1500 | 1500 x 1500 | 3000 x 1500 | 4500 x 1500

Thickness (mm): 0.5 | 0.8 | 1.0 | 1.5 | 2.0 | 3.0

show more...

* Other sizes and thicknesses can be accommodated upon request.

General application area, provided that chemical compatibility conditions and known installation principles are applied.

Maximum performance is ensured by adhering to the appropriate technical values in connection design and gasket installation. It is recommended to seek consultancy services.

Limited application area. Technical consultancy is mandatory.

In a known application, the best method to determine gasket compatibility is by using the P-T diagram. The highest values of P-T can be misleading. Maximum temperature and maximum pressure should not be used simultaneously. Maximum values are provided purely for indicative purposes. These values are related both to the gasket material properties and to the operating conditions. It is recommended to use the P-T diagram when selecting a gasket.

PACKINGS

FABRICS

SHEETS

PACKINGS

FABRICS

SHEETS

PACKINGS

FABRICS

SHEETS