PTFE - Sheet Film

Product Description

PTFE sheets are manufactured by pressing and sintering granular resin in a mold. It has excellent physical and chemical properties and offers a wide range of applications between -180°C and 260°C. PTFE can be reinforced with materials such as glass fiber, carbon, graphite, molybdenum disulfide, and bronze to improve its mechanical properties. Alloy materials enhance PTFE’s mechanical strength, stability, and wear resistance, while not adversely affecting its other properties. It boasts advantages such as resistance to chemical corrosion, weather resistance, excellent dielectric properties, high lubricity, non-stick nature, and durability against damage.

show more...

Application Areas

It has a wide range of applications between -180 °C and 260 °C. It is commonly used in cable manufacturing for aviation and computer technologies, in fuel and hydraulic lines due to its very low fluid resistance, in shafts due to low friction resistance, in the production of gaskets and seals used in pumps and valves, and in the manufacture of gear-like parts due to its non-stick property.

show more...

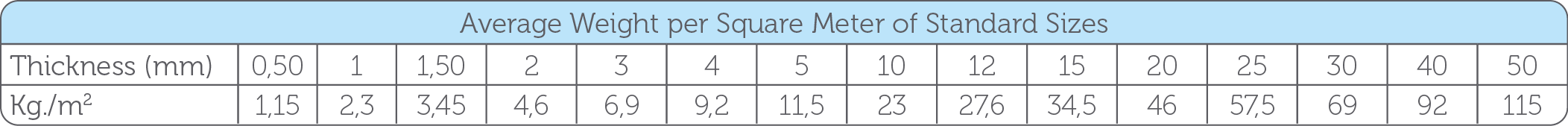

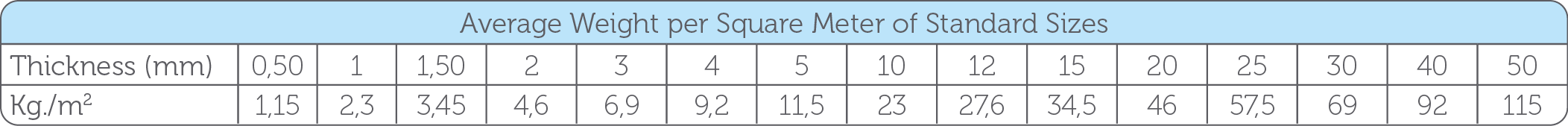

Meter / weights may vary.

PTFE - Sheet Film

Product Description

PTFE sheets are manufactured by pressing and sintering granular resin in a mold. It has excellent physical and chemical properties and offers a wide range of applications between -180°C and 260°C. PTFE can be reinforced with materials such as glass fiber, carbon, graphite, molybdenum disulfide, and bronze to improve its mechanical properties. Alloy materials enhance PTFE’s mechanical strength, stability, and wear resistance, while not adversely affecting its other properties. It boasts advantages such as resistance to chemical corrosion, weather resistance, excellent dielectric properties, high lubricity, non-stick nature, and durability against damage.

show more...

Application Areas

It has a wide range of applications between -180 °C and 260 °C. It is commonly used in cable manufacturing for aviation and computer technologies, in fuel and hydraulic lines due to its very low fluid resistance, in shafts due to low friction resistance, in the production of gaskets and seals used in pumps and valves, and in the manufacture of gear-like parts due to its non-stick property.

show more...

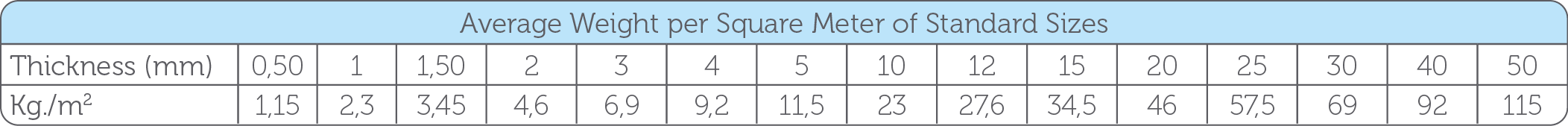

Meter / weights may vary.

PTFE - Sheet Film

Product Description

PTFE sheets are manufactured by pressing and sintering granular resin in a mold. It has excellent physical and chemical properties and offers a wide range of applications between -180°C and 260°C. PTFE can be reinforced with materials such as glass fiber, carbon, graphite, molybdenum disulfide, and bronze to improve its mechanical properties. Alloy materials enhance PTFE’s mechanical strength, stability, and wear resistance, while not adversely affecting its other properties. It boasts advantages such as resistance to chemical corrosion, weather resistance, excellent dielectric properties, high lubricity, non-stick nature, and durability against damage.

show more...

Application Areas

It has a wide range of applications between -180 °C and 260 °C. It is commonly used in cable manufacturing for aviation and computer technologies, in fuel and hydraulic lines due to its very low fluid resistance, in shafts due to low friction resistance, in the production of gaskets and seals used in pumps and valves, and in the manufacture of gear-like parts due to its non-stick property.

show more...

Meter / weights may vary.

PACKINGS

FABRICS

SHEETS

PACKINGS

FABRICS

SHEETS

PACKINGS

FABRICS

SHEETS