Ceramic Fiber Board (Sheet)

Product Description

Ceramic fiber board is a vacuum-formed material capable of withstanding higher gas velocities than ceramic fiber blanket. This material is widely used in furnaces, boiler inlets and outlets, and industrial plant chimney linings. Its low thermal conductivity and low heat capacity allow for quick interventions and rapid maintenance at the location where it is used.

show more...

Application Areas

In industrial furnaces

In combustion chambers, boilers, and heaters

As supportive material for brick and monolithic refractory materials

For transporting molten aluminum and molten non-ferrous metals

In expansion joints

show more...

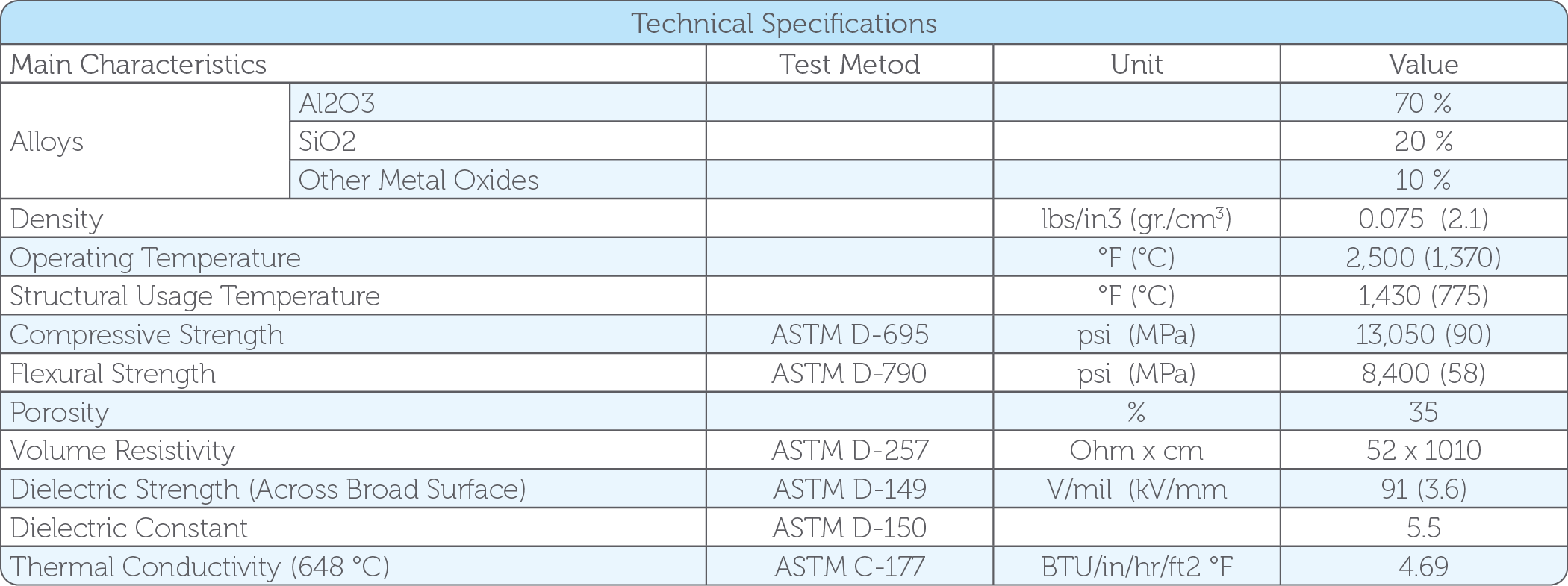

Specifications

Low thermal conductivity

Low heat capacity

Lightweight, does not require additional insulation

Excellent thermal shock resistance

Resistance to hot gas erosion

Resistant to most chemical corrosion

Ease of cutting, handling, and installation

Low sound transmission

Resistant to contact with molten aluminum and non-ferrous molten metals

Contains no asbestos

show more...

The fundamental conformity information mentioned here is believed to be accurate and reliable. However, our company does not assume any responsibility for issues that may arise in your applications. It is the user's responsibility to verify the suitability and performance of the material before use.

Ceramic Fiber Board (Sheet)

Product Description

Ceramic fiber board is a vacuum-formed material capable of withstanding higher gas velocities than ceramic fiber blanket. This material is widely used in furnaces, boiler inlets and outlets, and industrial plant chimney linings. Its low thermal conductivity and low heat capacity allow for quick interventions and rapid maintenance at the location where it is used.

show more...

Application Areas

In industrial furnaces

In combustion chambers, boilers, and heaters

As supportive material for brick and monolithic refractory materials

For transporting molten aluminum and molten non-ferrous metals

In expansion joints

show more...

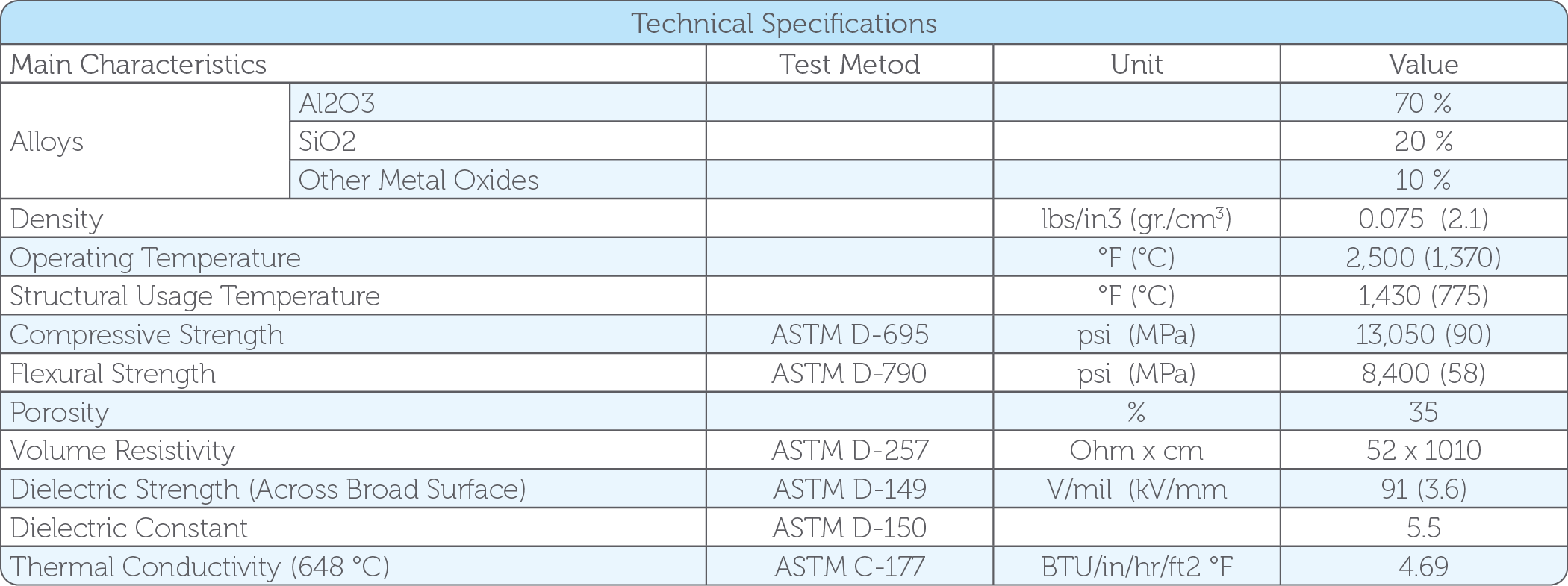

Specifications

Low thermal conductivity

Low heat capacity

Lightweight, does not require additional insulation

Excellent thermal shock resistance

Resistance to hot gas erosion

Resistant to most chemical corrosion

Ease of cutting, handling, and installation

Low sound transmission

Resistant to contact with molten aluminum and non-ferrous molten metals

Contains no asbestos

show more...

The fundamental conformity information mentioned here is believed to be accurate and reliable. However, our company does not assume any responsibility for issues that may arise in your applications. It is the user's responsibility to verify the suitability and performance of the material before use.

Ceramic Fiber Board (Sheet)

Product Description

Ceramic fiber board is a vacuum-formed material capable of withstanding higher gas velocities than ceramic fiber blanket. This material is widely used in furnaces, boiler inlets and outlets, and industrial plant chimney linings. Its low thermal conductivity and low heat capacity allow for quick interventions and rapid maintenance at the location where it is used.

show more...

Application Areas

In industrial furnaces

In combustion chambers, boilers, and heaters

As supportive material for brick and monolithic refractory materials

For transporting molten aluminum and molten non-ferrous metals

In expansion joints

show more...

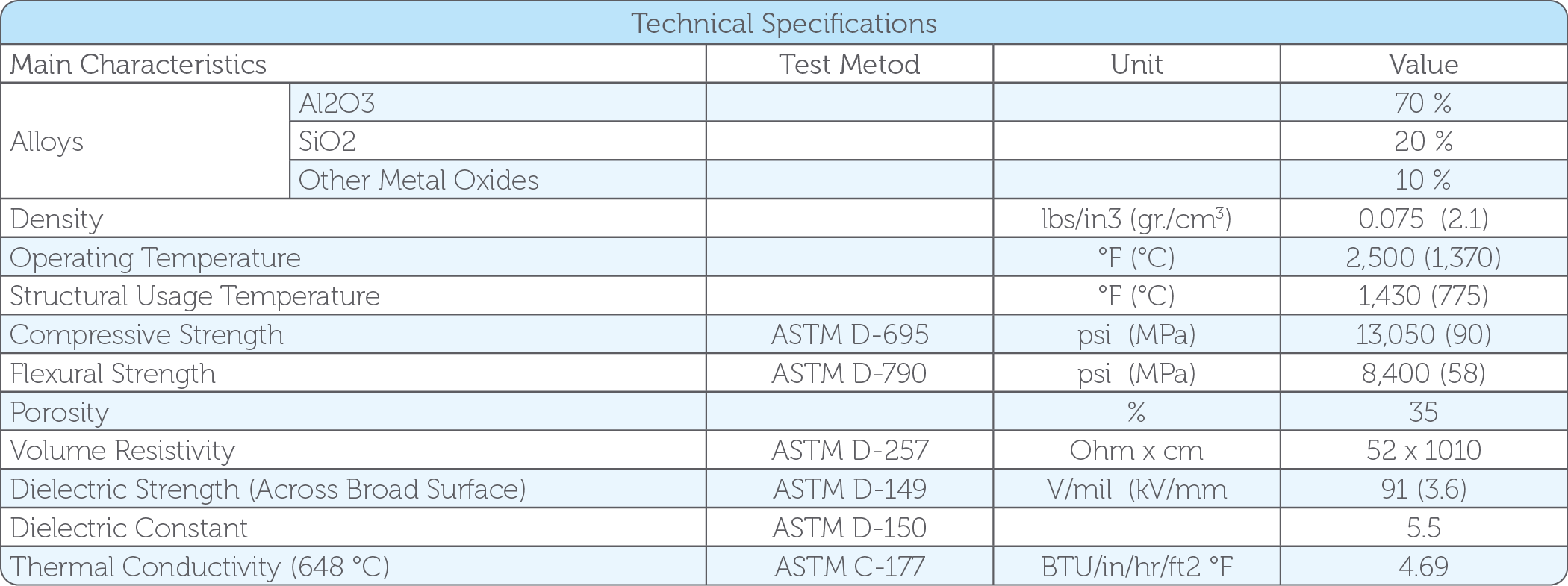

Specifications

Low thermal conductivity

Low heat capacity

Lightweight, does not require additional insulation

Excellent thermal shock resistance

Resistance to hot gas erosion

Resistant to most chemical corrosion

Ease of cutting, handling, and installation

Low sound transmission

Resistant to contact with molten aluminum and non-ferrous molten metals

Contains no asbestos

show more...

The fundamental conformity information mentioned here is believed to be accurate and reliable. However, our company does not assume any responsibility for issues that may arise in your applications. It is the user's responsibility to verify the suitability and performance of the material before use.

PACKINGS

FABRICS

SHEETS

PACKINGS

FABRICS

SHEETS

PACKINGS

FABRICS

SHEETS